Properties, Benefits & Uses of Teflon Hoses (PTFE)

PTFE, or Polytetrafluoroethylene, is the grandfather of fluoroplastics, a group of high-performance plastics with unique properties. Discovered by the scientist Roy J. Plunkett in 1938, PTFE, also known as Teflon®, is the most unusual fluoropolymer and exhibits the best performance in terms of temperature, chemical resistance, and non-stick properties.

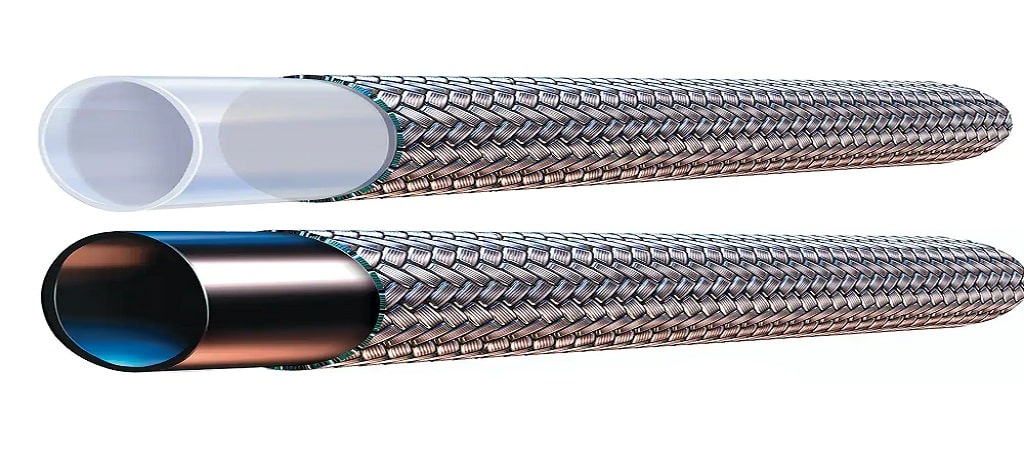

Teflon hoses, also known as PTFE (polytetrafluoroethylene) hoses, are highly durable and resistant to heat, chemicals, and friction. Here are some of the properties, benefits, and uses of Teflon hoses:

Properties:

- High-temperature resistance: Teflon hoses can withstand temperatures ranging from -60°C to +260°C, making them suitable for use in high-temperature environments.

- Chemical resistance: Teflon hoses are highly resistant to chemicals, including acids, alkalis, and solvents. They can also resist oxidation and degradation.

- Low friction: Teflon hoses have a low coefficient of friction, which makes them ideal for use in applications that require the transfer of viscous or sticky fluids.

- Non-stick: Teflon hoses have a non-stick surface, which makes them easy to clean and prevents the buildup of residue or debris.

Benefits:

- Durability: Teflon hoses have a long service life and can withstand repeated use in harsh environments.

- Versatility: Teflon hoses can be used in a wide range of applications, including chemical processing, food and beverage, pharmaceuticals, and automotive.

- Safety: Teflon hoses are non-toxic and can be used for transporting food or pharmaceutical products without contamination.

Uses:

- Chemical processing: Teflon hoses are used in chemical processing industries to transfer corrosive or hazardous fluids.

- Food and beverage: Teflon hoses are used in the food and beverage industry to transfer food products, such as dairy, wine, and beer.

- Pharmaceuticals: Teflon hoses are used in the pharmaceutical industry to transfer drugs, vaccines, and other medical products.

- Automotive: Teflon hoses are used in the automotive industry to transfer fluids, such as brake fluid and power steering fluid.

In summary, Teflon hoses are highly durable, versatile, and resistant to heat and chemicals. They are used in a wide range of industries, including chemical processing, food and beverage, pharmaceuticals, and automotive. Their non-stick surface and low friction make them easy to clean and suitable for transferring viscous or sticky fluids.

What are the properties of PTFE?

While a plastic molecule contains a carbon chain with hydrogen atoms attached, in a Polytetrafluoroethylene (PTFE) structure, the hydrogen atoms are replaced with fluorine atoms. This dramatically changes the property of the material and PTFE, like other fluoroplastics, has special properties:

- Very high working temperatures

- Non-stick characteristic

- Low friction surface

- Very high resistance to chemicals and solvents

- Very high electrical resistance

- Resistance to weather, UV light and corrosion

- Inert, non-toxic and bio-compatible

What are the advantages and disadvantages of PTFE?

PTFE is the most unusual fluoropolymer and exhibits the best performance in terms of temperature, chemical resistance and non-stick properties. In addition, PTFE also enjoys the following benefits:

- Best price : performance ratio

- Continuous working temperature of +260°C – This is the highest working temperature for any fluoroplastic

- Resistance to nearly all chemicals

- Low friction surface – Even a gecko would slip on PTFE

- Very high electrical resistance

- Translucent colour (when the correct raw polymer grade is chosen)

The main disadvantage of PTFE is that it does not actually melt when heated and is therefore difficult to process. Very unconventional techniques are needed to mould, extrude and weld this fluoropolymer.

What is PTFE used for?

Thanks to its extraordinary properties, PTFE is able to endure even the harshest of environments and as such, is suitable for use in numerous applications. This fluoroplastic is ideal for use in the food and drink production, from cooking equipment to food coverings, conveyor belt rollers, temperature sensor casing and non-stick surface covers.

In the chemical industry, PTFE can be used to make different products, from gaskets to vessel linings and chemical tanks. PTFE is also widely used in high temperature applications, from fire critical applications to terminal insulation on heating elements and jet engines, UV lamps and external aircraft fittings.

PTFE material is ideal for use in medical applications and for the production of internal and external life-saving equipment such as catheters, bio-containment vessels, syringes and sutures. This unique fluoropolymer is also perfect for electrical insulation and the protection of electronic components.